Total Harmonic Distortion (THD) from dBc

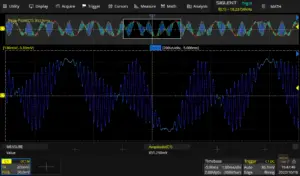

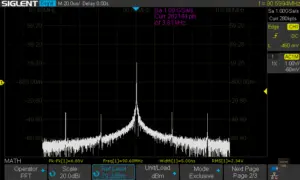

This article supplements to my article titled THD Measurement with an Oscilloscope and FFT, which appeared in Elektormagazine. Here I will explain how the formula to calculate THD-F from relative power values (in dBc) was derrived from the standard voltage-ratio formula. A more in-depth explanation of the entire subject can be found in my research paper titled Total Harmonic Distortion (THD) analysis utilizing the FFT capabilities of modern digital storage oscilloscopes.